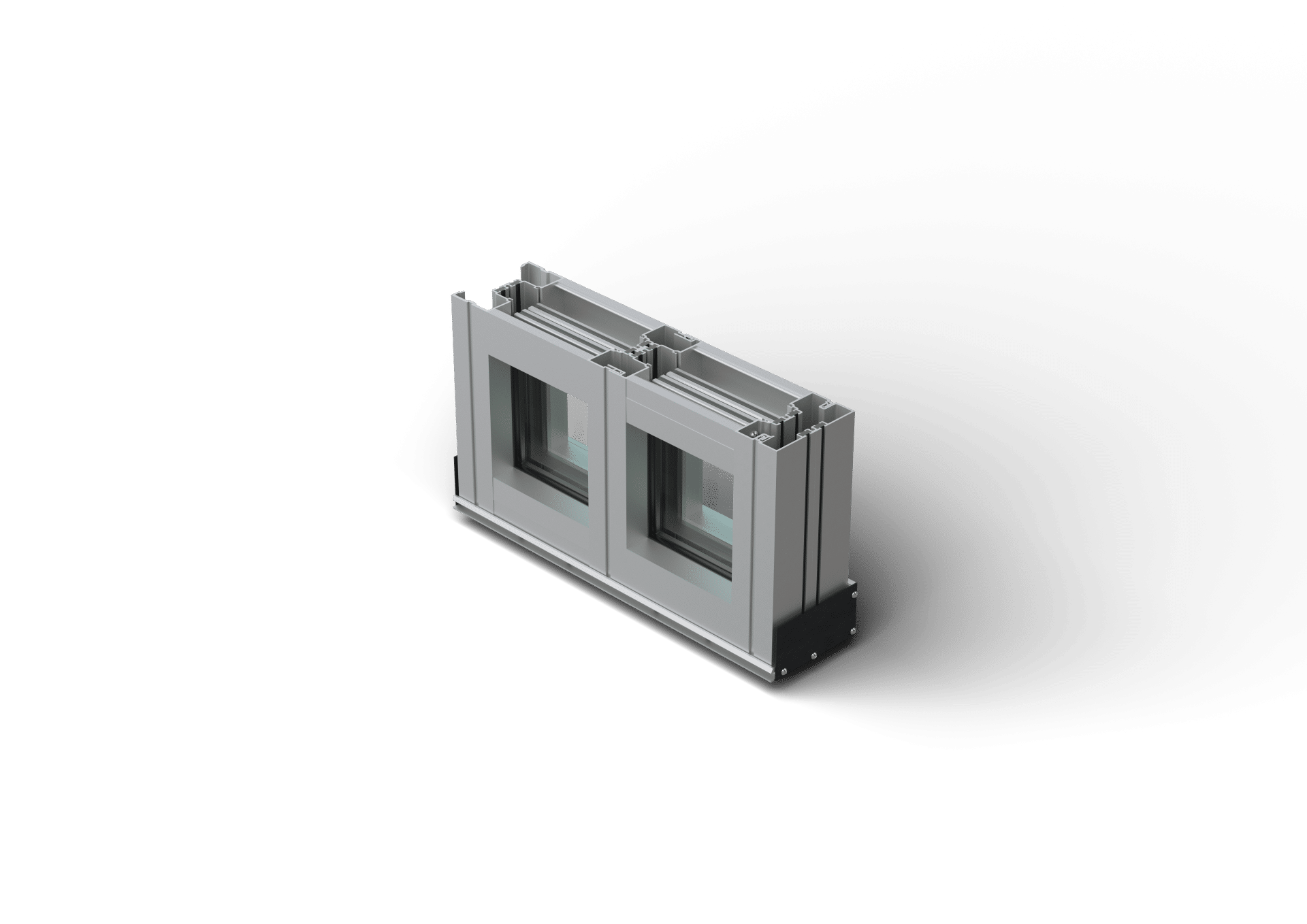

- Two distinct looks – a sub-sash option for equal sightlines across the opening and a direct field-glazed option for a more traditional sliding door look with optional interior screens

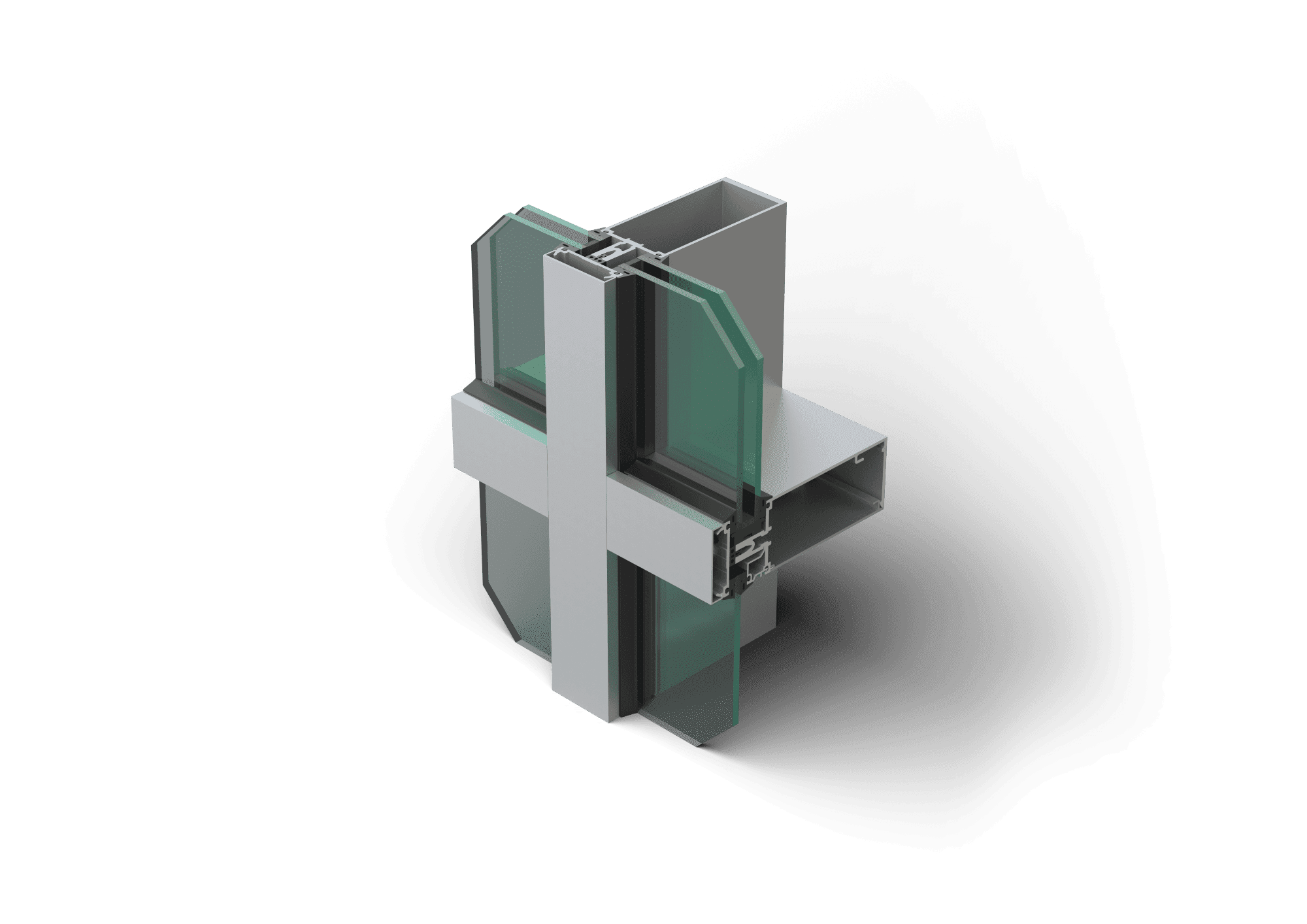

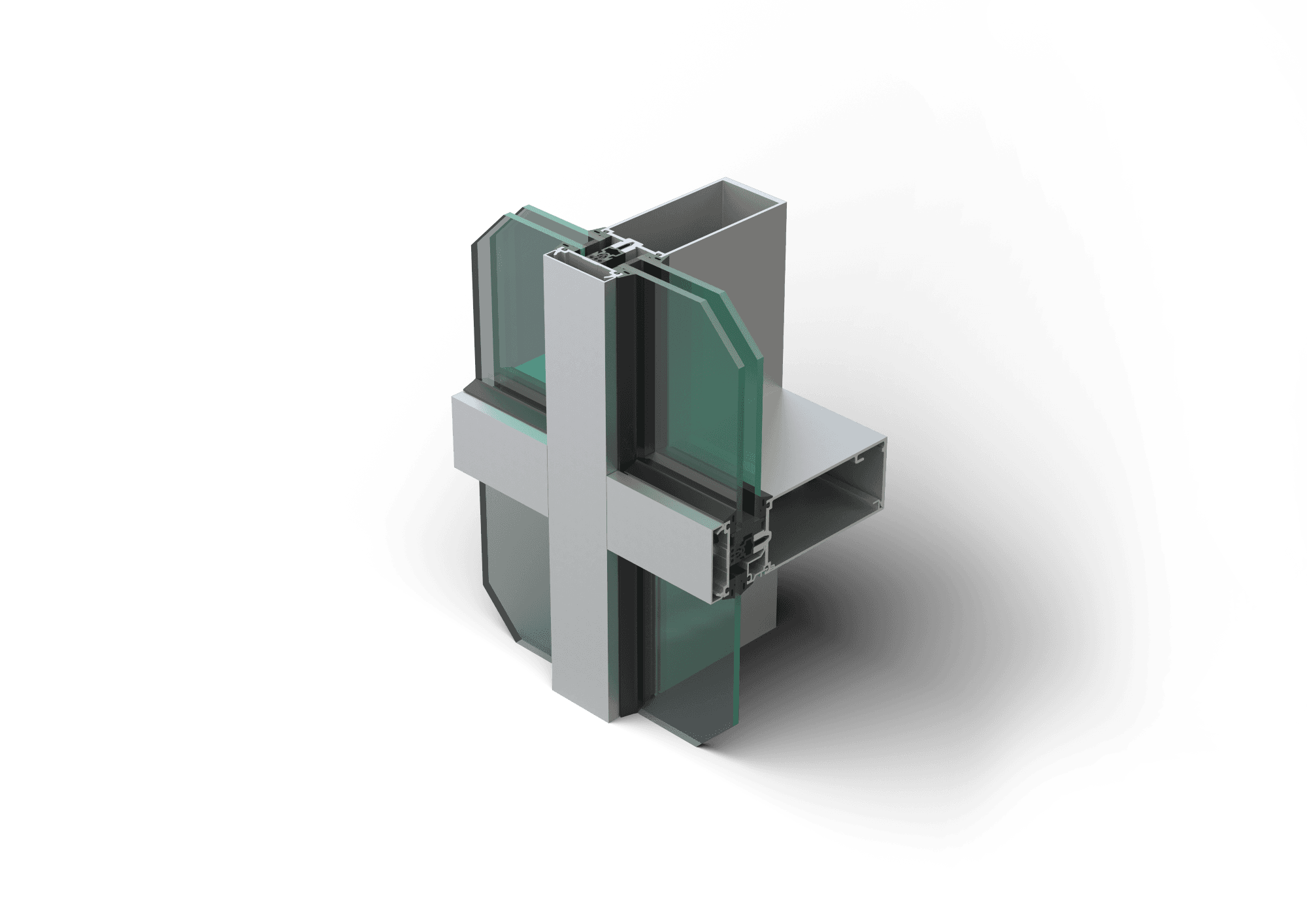

- 2-1/4” (57.15mm) standard sill, with 15 psf water performance, provides a smaller sightline at the interior/exterior transition

- Coped, screw spline joinery for easier fabrication and assembly

- Pre-glazing of the sliding panel and sub-sash fixed panel with a common glass size for quicker glazing and installation

- Open view slab-to-slab units that can span up to 10’ tall, providing occupants clear, unobstructed views

- A larger wheel, stainless steel tandem roller with precision ground sealed bearings, allows smooth operation of even the largest and heaviest sliding panels

- Unique beveled profiles that create architectural shadow lines and permit a commercial product to receive mid- to high-rise residential acceptance

- Meeting the challenges of high winds, heavy rain, blizzards and hurricanes, it offers a practical product solution for use on high-end condominiums, hotels and apartments

- Fixed panels can be stacked via a common mullion to achieve even greater expanses of glass (OOXO) in addition to the standard OX, XO, OXO and OXXO openings

Hurricane Resistant

Find out more here.

Thermal Technology

Find out more here.

Related Product Approvals

Find out more here.

AA®3200 Thermal Sliding Door - Architectural Detail Manual

7 MB

Product Selection Guide Standard Entrances

2 MB

AA®3200 Thermal Sliding Door - Flyer

741 KB

Florida Product Approval & Texas Dept. of Insurance Evaluation Documents

290 KB

Anodized and Painted Aluminum Extrusions - EPD

765 KB

Finishes Information - Architectural Detail Manual

238 KB

Anodize Finishes - Color Chart

82 KB

Liquid Paint - Color Chart - Permadize®

794 KB

Liquid Paint - Color Chart - Permafluor™

268 KB

AA®3200 Thermal Sliding Door - English

AA®3200 Thermal Sliding Door - French

AA®3200 Thermal Sliding Door

Typical Details for "OOX" Configuration

Typical Details for "OX" Configuration

Typical Details for "OXO-L" Configuration

Typical Details for "OXO-R" Configuration

Typical Details for "OXXO" Configuration

Typical Details for "XO" Configuration

Typical Details for "XOO" Configuration

Typical Details for "OOX" Configuration

Typical Details for "OX" Configuration

Typical Details for "OXO-L" Configuration

Typical Details for "OXO-R" Configuration

Typical Details for "OXXO" Configuration

Typical Details for "XO" Configuration

Typical Details for "XOO" Configuration

Typical Details for "OOX" Configuration

Typical Details for "OX" Configuration

Typical Details for "OXO-L" Configuration

Typical Details for "OXO-R" Configuration

Typical Details for "OXXO" Configuration

Typical Details for "XO" Configuration

Typical Details for "XOO" Configuration

Typical Details for "OOX" Configuration

Typical Details for "OX" Configuration

Typical Details for "OXO-L" Configuration

Typical Details for "OXO-R" Configuration

Typical Details for "OXXO" Configuration

Typical Details for "XO" Configuration

Typical Details for "XOO" Configuration

Typical Details for "OOX" Configuration

Typical Details for "OX" Configuration

Typical Details for "OXO-L" Configuration

Typical Details for "OXO-R" Configuration

Typical Details for "OXXO" Configuration

Typical Details for "XO" Configuration

Typical Details for "XOO" Configuration

Typical Details for "OOX" Configuration

Typical Details for "OX" Configuration

Typical Details for "OXO-L" Configuration

Typical Details for "OXO-R" Configuration

Typical Details for "OXXO" Configuration

Typical Details for "XO" Configuration

Typical Details for "XOO" Configuration

Kawneer - AA3200 HP-Sub Sash OOX.rfa

Kawneer - AA3200 HP-Sub Sash OX.rfa

Kawneer - AA3200 HP-Sub Sash OXO-L.rfa

Kawneer - AA3200 HP-Sub Sash OXXO.rfa

Kawneer - AA3200 IR-Sub Sash (OOX) LMI.rfa

Kawneer - AA3200 IR-Sub Sash (OX) LMI.rfa

Kawneer - AA3200 IR-Sub Sash (OXO-L) LMI.rfa

Kawneer - AA3200 IR-Sub Sash (OXXO) LMI.rfa

While most of our products are not hazardous in and amongst themselves, hazardous properties can develop when the product is altered through cutting, welding, and grinding. Details on the specific hazards that can develop and the proper protective measures to use can be found in the SDSs.

Arconic’s SDS database provides PDF files of safety information on specific materials. The SDS ID numbers (product code) and description for materials used in Kawneer products are listed below.

SDS # DESCRIPTION / TITLE

1405 – Kawneer Thermal Break Filled Extrusions

1385 – Kawneer Acrylic Paints

1386 – Kawneer Fluoropolymer Paints

1526 – Kawneer Bloomsburg Solvent Recovery Still Residuals

1387 – Painted Architectural Aluminum Extrusions

509 – Aluminum Extrusions, Anodized Aluminum Products

Search Arconic’s SDS database for safety information on specific materials.

Project Warranty Cover Sheet (English)

137 KB

Project Warranty Cover Sheet (French-Canadian)

137 KB

Project Warranty Cover Sheet Sample (English)

139 KB

Project Warranty Cover Sheet Sample (French-Canadian)

140 KB

Material & Workmanship - English

185 KB

Material & Workmanship - French

190 KB

Material & Workmanship Sample (English)

203 KB

Material & Workmanship Sample (French Canadian)

212 KB

Anodized Finishes Warranty - English

523 KB

Anodized Finishes Warranty - French

517 KB

Anodized Finishes Sample (English)

529 KB

Anodized Finishes Sample (French Canadian)

524 KB

Painted Finishes Warranty - English

557 KB

Painted Finishes Warranty - French

538 KB

Painted Finishes Sample (English)

565 KB

Painted Finishes Sample (French Canadian)

550 KB

Insulating Glass Warranty - English

498 KB

Insulating Glass Warranty - French

499 KB

Insulating Glass Sample (English)

502 KB

Insulating Glass Sample (French Canadian)

504 KB

Laminated Glass Warranty - English

122 KB

Laminated Glass Warranty - French

123 KB

Laminated Glass Sample (English)

126 KB

Laminated Glass Sample (French Canadian)

128 KB

Corrective Field Repairs (English)

154 KB

Corrective Field Repairs (French-Canadian)

152 KB